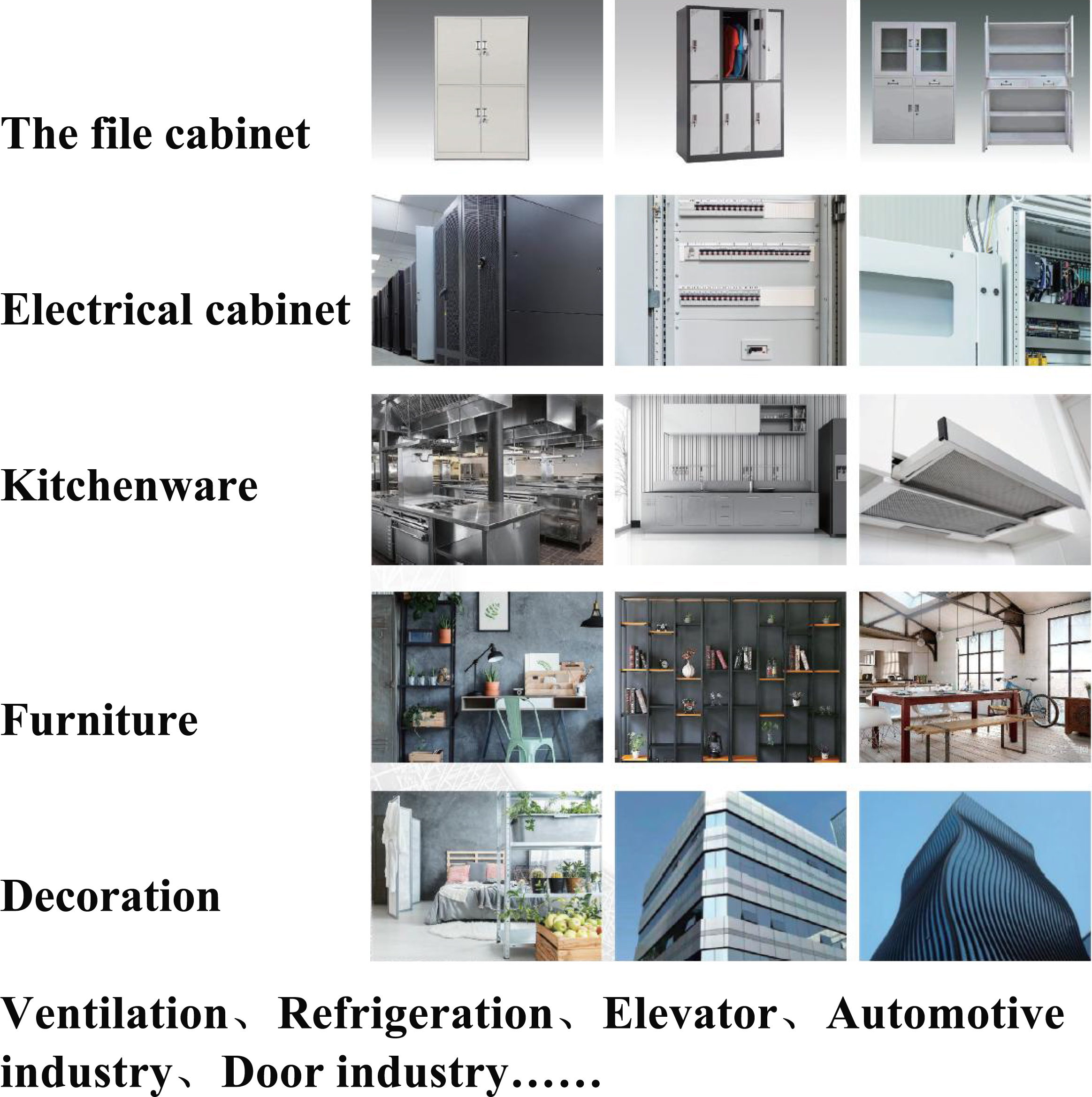

The panel bender can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets...), kitchen utensils (refrigerators, air conditioners, stoves...) , Furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields

PARAMETER

Panel Bender is widely used in sheet metal processing, decoration, metallurgy, shipbuilding, automobile, machinery, aviation and other professional production fields. With stable product quality and continuous growth, it is committed to becoming an advanced enterprise in the domestic medium and high-end sheet metal processing and forming machine tool industry.

| Contain | Advanced instruction Arc command Three-axis automatic positioning function Plate error-proof detection Double C-axis automatic follow Oil supply self-lubricating system Thickness detection Partial load detection Automation components (open interface) High-speed console Pleated edge (cold plate shall not exceed 1.0mm) Hand wheel Advanced instruction | |

| Minimum inside dimensions for four-sided forming(Without inside flange) | 140mmx210mm | |

| Max. bending speed | 0.2 s/time | |

| Max. bending width | 1000 mm (1000X) 1400 mm (1400X) | |

| Max. bending size | L 1000mm * W 1000mm (1000X) L 1400mm * W 1400mm (1400X) | |

| Max. bending height | 170 mm | Height without hinge blade |

| Max. bending thickness(Thickness can be customized) | UTS 515N/mm2 201 Stainless steel 0.8mm UTS 520N/mm2 304 Stainless steel 1.0mm UTS 410N/mm2 Cold plate 1.2mm UTS 265N/mm2 Aluminum plate 1.6mm | |

| Rated voltage | 380V | |

| Average power | 1.1KW | |

| Noise | 50 dB | |

| Overall dimensions | L 285cm * W 150cm * H 280cm (1000X) L 365cm * W 190cm * H 290cm (1400X) | |

| Total mass | 7 tons (1000X) 10 tons (1000X) | |

| User operating environment | Operating system above Win7 | |

| CNC control system | New independent research and development of 9-axis + linkage full-servo CNC system | |

| Upper press tool | Straight punch | |

| Lower press tool | Curved tool | |

| Special customization | Provide bending workpiece drawing | |

DESCRIPTION

Our equipment is designed and produced according to the high precision machine standards,the main lathe bed adopts high grade castings,and the casting and weld assembly are all subjected to strict stress relieving process,also,they are produced integrated by ultra precision machine tool,finally,with the strictly control by our high precision detector,our machines can ensure the higher accuracy,higher stability and higher rigidity during there long-time running period.

High Grade Casting

High Grade Casting

Equipment core framework using high grade QT500-7 and HT250 castings,and must be measured by a testing instrument.After precise finite element force analysis,the frame adopts the most stable triangular interconnection design,which greatly guarantees the stability under high tonnage impact force.

High Welding Standard

High Welding Standard

No matter big and small,in the whole welding process adopts carbon dioxide protection welding.Every welding place use full welding technology to ensure the welding workpiece is strong and beautiful.

Thoroughly Eliminate Stress

Thoroughly Eliminate Stress

Both casting and welding support mesa,adopt high precision temperature control furnace, according to the material of the corresponding gtemperature curve to make multiple tempering,annealing and other heat treatment process,then enough long full frequency vibration aging treatment,completely release the interal stress of workpiece,ensure that used for a long time not to be out of shape.

Precision Machining

Precision Machining

Different fixtures are designed for different workpieces,and the high-precision multi-axis machining center is used to finish the workpieces,which ensure the consistency of the precision before and after clamping.

Strict Testing

Strict Testing

Using high-precision micrometer U meter,with marble platform and marble square feet with tens of millions of years of aging,accurate measurement for each workpiece,control the processing quality of each workpiece strictly and check on strictly,to ensure that the assembly precision of the whole machine meets the standard of high-precision machine tools.

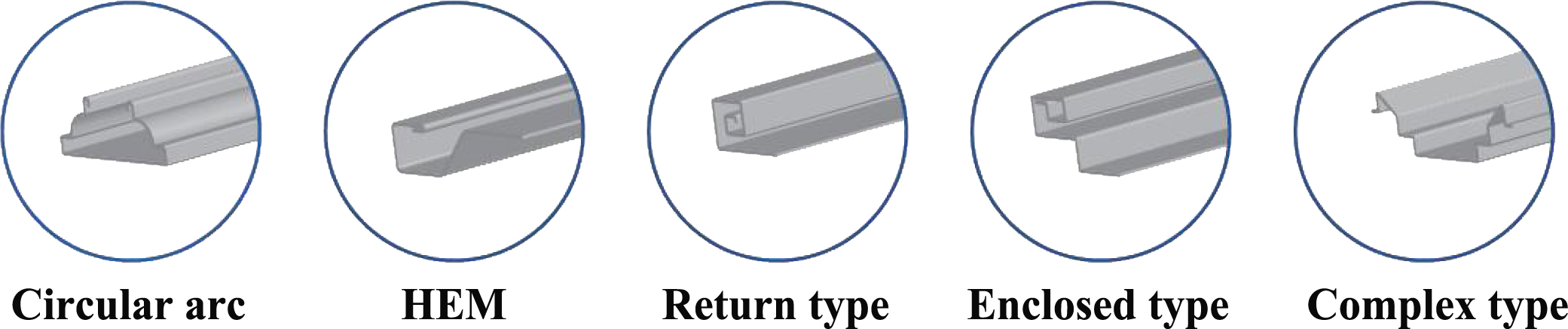

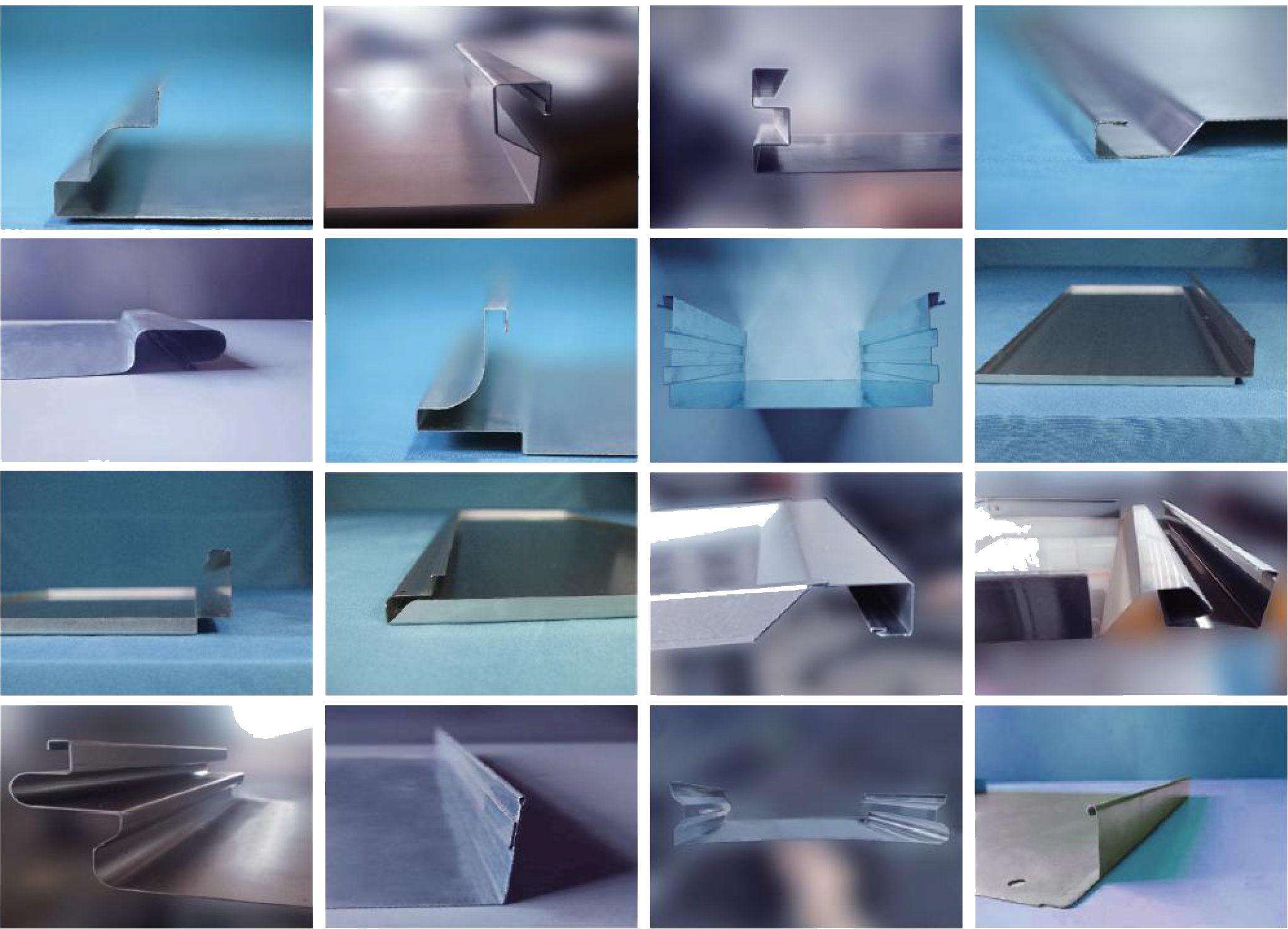

Technology Show

Workpiece Display

Application Field

Why Choose Us

Faster speed

Faster speed

The speed of 0.2 seconds per operation simple easy to knife,let you several times efficiency,effciently reduce labor costs,really save both time and labour,and don't have to worry.

Independent R&D

Independent R&D

Control system completely independent research and development,with the core patent,support flexible customization,lift the subsequent upgrade.

Easy to operate and learn

Easy to operate and learn

The labor requirement is greatly reduced,and we conduct research according to the usage habits of the public,easy to learn and easy to use,remove mobility problems.

More stringent quality control

More stringent quality control

In order to make the quality reach the highest,we make checks at all levels,from products to sales.

Don't worry about maintenance

Don't worry about maintenance

The whole machine is guaranteed for 12 months,pure electric servo,no special maintenance is required daily.

More economical and energy efficient

More economical and energy efficient

The product has high work efficiency and can greatly save labor cost.The average power consumption is only 1.5-2.8KW.h.

Related Products

Related Case

May. 17, 2023

The products are widely used in sheet metal processing, decoration, metallurgy, shipbuilding, automobile, machinery, aviation and other professional production fields. With stable product quality and continuous growth, it is committed to becoming an advanced enterprise in the domestic medium and high-end sheet metal View More+

Anhui Hisman Intelligent Equipment Manufacture Co., Ltd. is located in A-8#,Dahe Industrial Park,Bowang Town, Bowang District,Maanshan City,Anhui Provence,China.

Tel: +86 0555 6776 471

Email: Tim@ahhisman.com

Fax: +86 0555 6765 075

Phone: +86 138 5551 1880

Add: A-8#, Dahe Industrial Park, Bowang Town, Bowang District, Maanshan City, Anhui Province, China

INQUIRY